Transformer oil centrifuge

Transformer oil centrifuge service typically involves several key steps to ensure the effective operation of the equipment and the quality of the transformer oil. Here’s a general outline of what such a service might entail:

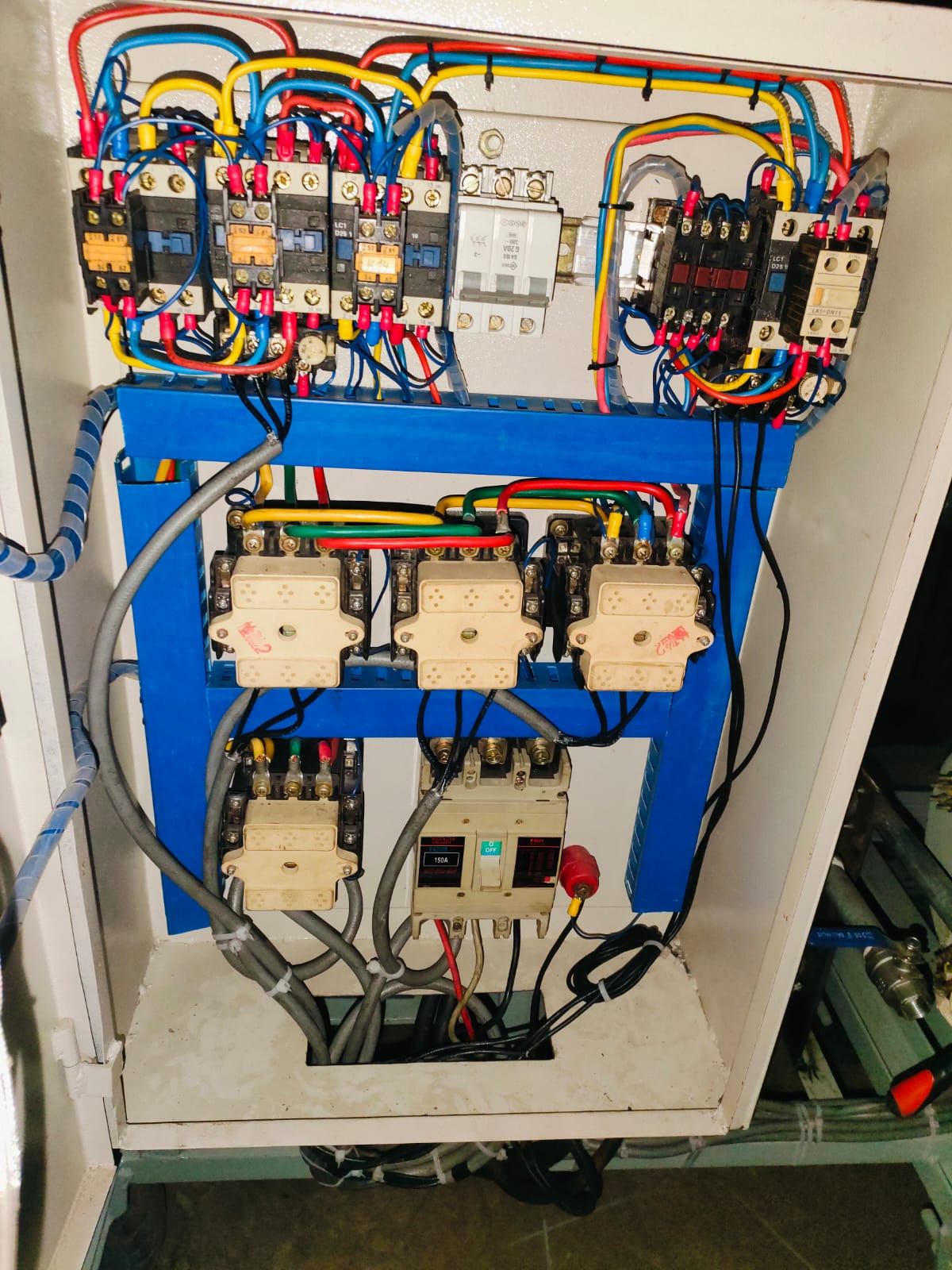

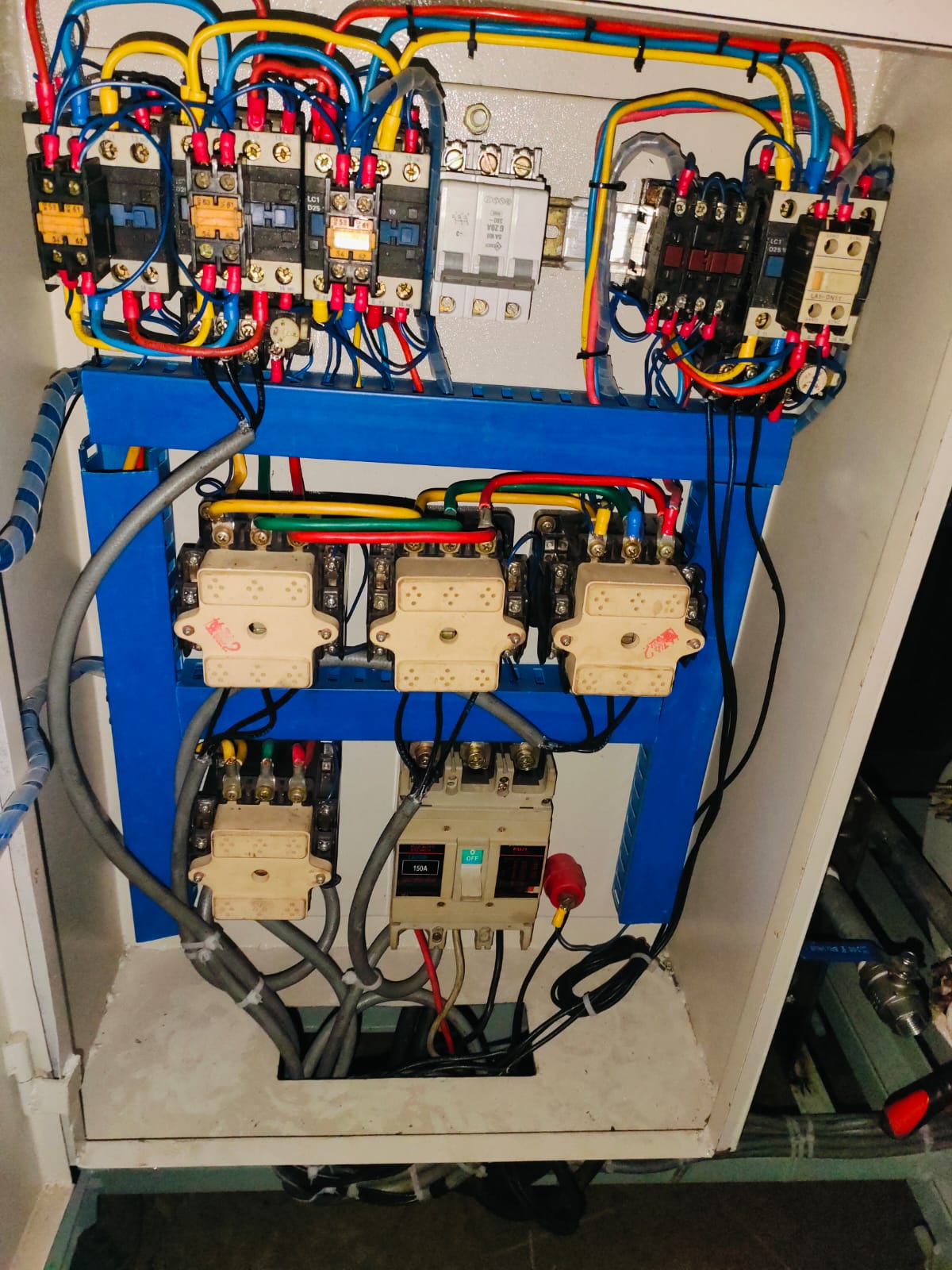

Equipment Inspection: A thorough inspection of the centrifuge is conducted to check for any signs of wear, damage, or malfunction. This includes inspecting components such as the centrifuge bowl, motor, drive system, seals, and controls.

Cleaning and Maintenance: The centrifuge is cleaned to remove any accumulated dirt, debris, or contaminants. This may involve disassembling certain components for a more thorough cleaning. Additionally, routine maintenance tasks such as lubrication of moving parts and replacement of worn-out components are performed as needed.

Calibration and Adjustment: The centrifuge may need to be calibrated and adjusted to ensure it operates at the correct speed and efficiency. This may involve checking and adjusting parameters such as rotational speed, balance, and alignment.

Testing: Various tests are conducted to assess the performance of the centrifuge and the quality of the transformer oil after processing. This may include oil quality testing to measure parameters such as moisture content, dielectric strength, acidity, and contamination levels.

Repairs and Replacement: Any defective or worn-out components identified during the inspection are repaired or replaced to restore the centrifuge to optimal working condition. This may involve replacing worn bearings, seals, gaskets, or electrical components.

Documentation and Reporting: Detailed records of the service activities performed, test results, and any recommendations for further action are documented. This information helps track the maintenance history of the centrifuge and provides valuable insights for future servicing needs.

Training and Support: Depending on the service provider, training and support may be offered to ensure that operators understand how to properly operate and maintain the centrifuge for optimal performance and longevity.

Overall, transformer oil centrifuge service is essential for maintaining the reliability and efficiency of transformer equipment in electrical power systems. Regular servicing helps prevent equipment failures, extends the lifespan of the centrifuge, and ensures the quality of the transformer oil, ultimately contributing to the overall reliability and performance of the power system.